–SLURRY pump

A slurry pump is a type of pump designed for pumping liquid containing solid particles. Slurry pumps changes in design and construction to adjust to multiple type of slurry which varies in concentration of solids, size of solid particles, shape of solid particles, and composition of solution.

–Vertical Sump Pump

Vertical sump pumps are intended for use in the industrial pumping applications to pump clean or lightly contaminated liquids, fibrous slurries and liquids containing large solids from the deep sumps. The pumping head is suspended into the pumped liquids and the drive motor is dry installed on the top.

–Seal less diaphragm pumps

Hydra-Cell positive displacement diaphragm pumps feature a seal-less pumping chamber so there are no seals, packing or cups to leak or replace. The seal-less design and check valves enable Hydra-Cell to handle abrasives and particulates that would damage other types of pumps.

–DOSING pump

A dosing pump is a positive displacement pump that is designed to inject a chemical or any other substance into the flow of water, gas or steam. Dosing pumps are typically small and provide an extremely precise flow rate for maximum control.

–Gear Pump

A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications

–Vane Pump

A vane pump is a type of rotary positive displacement pump. It consists of vanes mounted radially on a cylindrical rotor, which is eccentrically located in the pump casing. The vanes maintain a close seal against the casing wall.

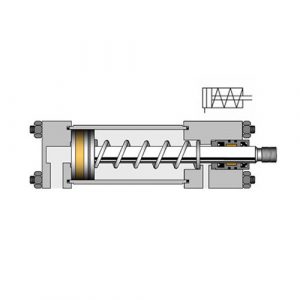

–Screw Pump

Screw pumps operate using two counter-rotating screw rotors which are engineered so that they rotate “towards each other”. This traps the gas in the space between the “screws” of their rotors. As the screws rotate, this trapped volume decreases which not only compresses the gas but moves it towards the exhaust

–Lobe Pump

The lobes create flow by creating exposed cavities for the liquid to flow into which are then rotated towards the outside of the pump casing and expelled through the outlet of the pump. Liquids do not pass between the lobes and pass through the outlet ports.

–High pressure Centrifugal pumps

High-pressure pumps generate the operating pressure and supply water to the spraying device. Generally, they can be divided into positive displacement pumps and hydraulic intensifiers. Positive displacement pumps are standard for hydrodemolition applications.

–Medium pressure water pumps

The term medium-pressure pump means a centrifugal pump with a head between 80 and 200 m, as in irrigation pumps. Alternatives for other heads are the low-pressure, high-pressure and super-pressure pumps.

Reviews

There are no reviews yet.